Induction Heating Pipe Bending Machine

- group name

- Induction Heating Pipe Bending Machine

- Min Order

- 1 piece

- brand name

- WONSTEN

- model

- YWG Series

- Nearest port for product export

- Shanghai, Qindao, Tianjin, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A

- update time

- Wed, 27 Jan 2021 13:29:06 GMT

Paramtents

Product Name Induction Pipe Bending Machine

Processing Method Induction Heating

Processing Material Metal Pipes

Packging & Delivery

-

Min Order1 piece

Briefing

The Intermediate frequency pipe bending process is the most ffective one among all kinds of existing pipe bending processes.

Detailed

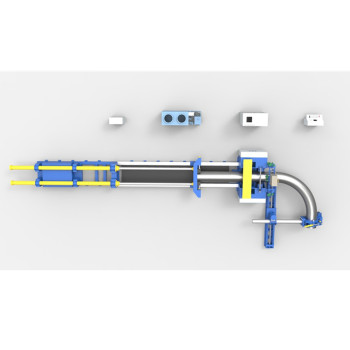

Induction heating pipe bending machine uses intermediate frequency induction heating to bend the workpiece under the condition of local heating. Compared with the general cold pipe bending machine, it not only does not need a complete set of special mold, and the volume of the machine only accounts for the same specification of cold pipe bending machine 1/3 ~ 1/2.

The process of intermediate frequency bending is to cover the bending part of the steel tube with an induction ring, use a mechanical rotary arm to catch the pipe head, and pass a high-density if current into the induction ring to heat the steel tube. When the temperature of the steel tube rises to the plastic state, the steel tube is pushed forward by mechanical thrust at the back end of the steel tube for bending. Simple process flow: namely side heating, side pushing, side bending, side cooling, finish bending control.