Automatic Induction Heating Pipe Bender

- group name

- Induction Heating Pipe Bending Machine

- Min Order

- 1 piece

- brand name

- WONSTEN

- model

- YWG Series

- Nearest port for product export

- Shanghai, Qindao, Tianjin, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A

- update time

- Wed, 27 Jan 2021 13:31:16 GMT

Paramtents

Product Name Induction Pipe Bending Machine

Warranty 2 Years

Usage Metal Pipe Induction Heating Bending

Packging & Delivery

-

Min Order1 piece

Briefing

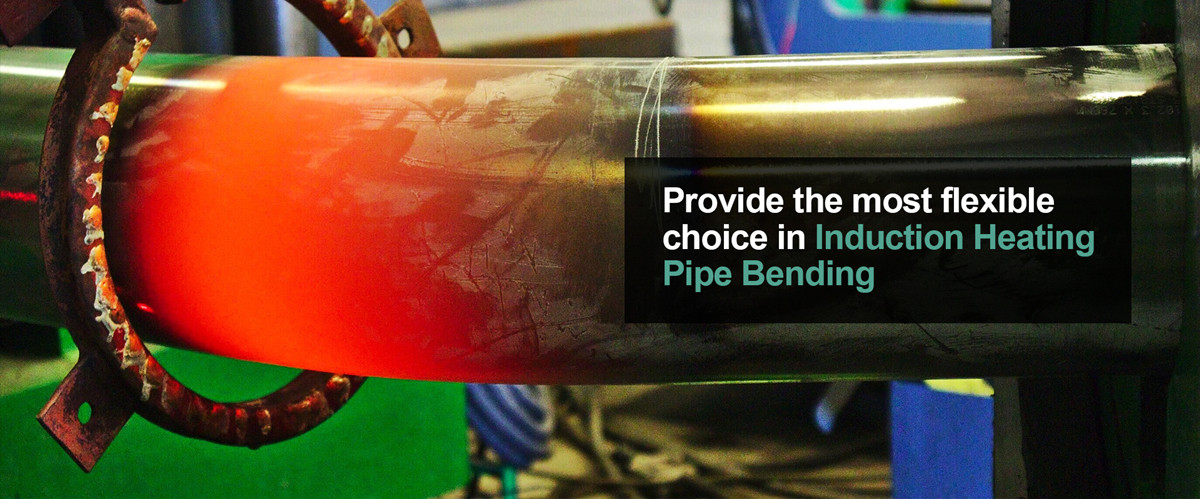

Heat induction bending is a fully automated process of hot bending, which uses an induction bending heating coil.

Detailed

The induction bending coil of Induction heating pipe bending machine creates a narrow, circumferential, heated band around the material to be bent while a clamp holds the material to its specific shape on a pivoting arm to the desired radius. When the appropriate temperature is reached, the heated tube/pipe material is shaped into a bend as it is pushed forward through the induction bending coil at a consistent speed and temperature. After the material passes through the induction bending coil, and the heat induction bending portion is complete, the bent tube/pipe is cooled by forced air or water, or it may be allowed to cool naturally at ambient temperatures.