Cnc Mandrel Pipe Bending Machine

- group name

- CNC Mandrel Tube Bender

- Min Order

- 1 piece

- brand name

- WONSTEN

- model

- 38CNC

- Nearest port for product export

- Shanghai, Qindao, Tianjin, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A

- update time

- Wed, 27 Jan 2021 14:27:07 GMT

Paramtents

Product Name CNC automatic Tube Bending Machine

Bending Hydraulic or Servo Motor

Feed and Rotary Servo Motor

Warranty 2 Years

Packging & Delivery

-

Min Order1 piece

Briefing

High product bending precision (±0.01mm) and good repeatability

Detailed

Owning cnc mandrel bending machine presents various advantages for shop owners. The cost of outsourcing your exhaust pipe bending duties to off-site facilities adds up quickly while leaving you dependent on sources out of your control.

If the idea of gaining control over your production and improving your timeline seems expensive or too good to be true, you’re in luck. Wonsten is the worldwide leading manufacturer of cnc mandrel bending machine with a variety of new exhaust pipe benders for sale. Our diverse collection of different bending machines gives you the opportunity to find the perfect solution for your production needs. We have a long history of reliability and share a passion for presenting facilities with the bending solution they need to further their own growth.

China CNC Pipe Bending Machine for Sale

High product bending precision (±0.01mm) and good repeatability

Easy for operation, suitable for high volume production

Multi-layer dies can be installed for tubes with multi-radius, making complicated bending easier

Automatic loading or unloading device can be installed for unmanned automatic operation.

This is a title

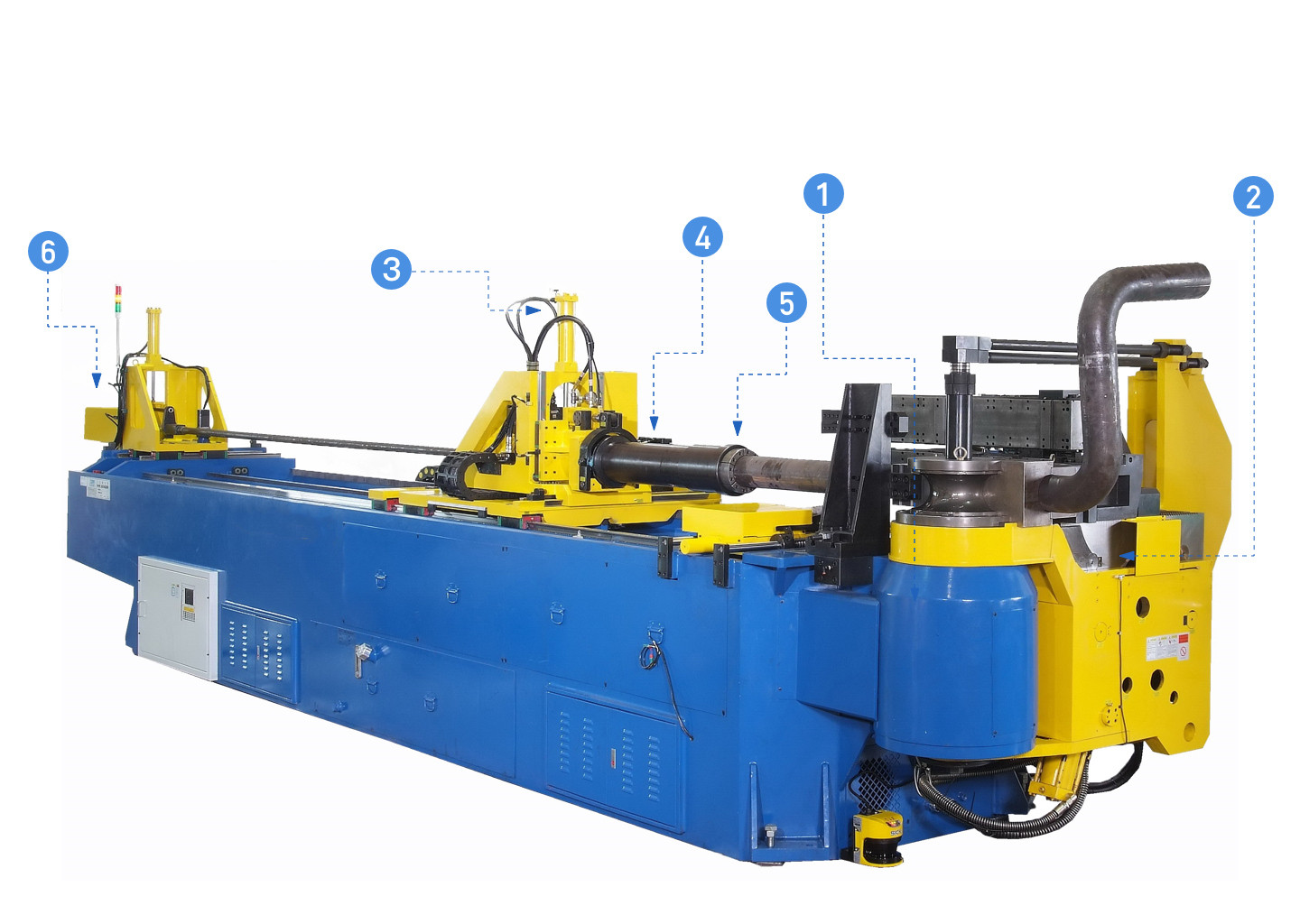

1. bend-arm (C-axis) by hydraulic

2. clamp die, pressure die and side booster by hydraulic

3. motion up-down and motion left-right by hydraulic

4. carriage (Y-axis) by servo motor with programmable speed

5. collet (B-axis) grip by hydraulic, rotation by servo motor

6. mandrel by hydraulic with automatic lubrication & anticipated

retraction

7. IPC based controller :

Industrial PC assorted with touch-screen display, convertible

between manual / automatic mode, convertible between inch

metric setting, convertible between XYZ / YBC axes

capable of reading igs/stp file

8. PLC based controller :

PLC controller with touch screen display, convertible between

manual / automatic mode, convertible between XYZ / YBC axes

(optional)