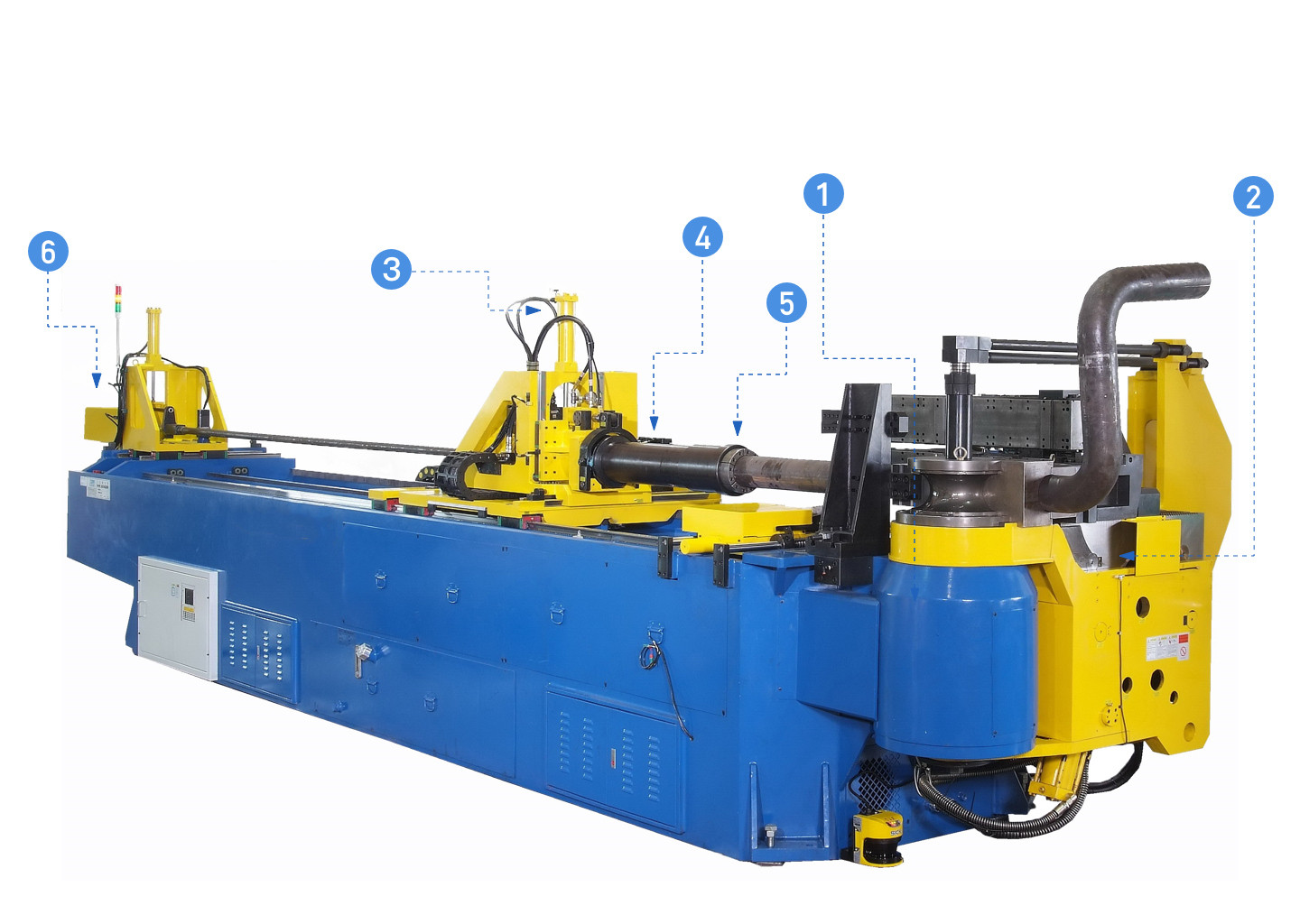

CNC Automatic Pipe Bending Machine

- group name

- CNC Mandrel Tube Bender

- Min Order

- 1 piece

- brand name

- WONSTEN

- model

- 75CNC

- Nearest port for product export

- Shanghai, Qindao, Tianjin, Ningbo

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, D/P D/A

- update time

- Wed, 27 Jan 2021 14:24:45 GMT

Paramtents

Product Name CNC Automatic Pipe Bending Machine

Bending Hydraulic or Servo Motor

Controller PLC or IPC

Feed and Rotary Servo Motor

Packging & Delivery

-

Min Order1 piece

Briefing

The Automatic Hydraulic Pipe Bending Machine plays an important role in construction and other fields.

Detailed

Product Feature

China CNC Pipe Bending Machine plays an important role in construction and other fields, with high and reliable performance. The steel bar conveying table is composed of multiple power rollers, which complete the automatic conveying of steel bars and the storage of left and right. The lifting mechanism is pneumatically controlled, which can automatically position the reinforcing bar on the double bending machine head and transfer the bent reinforcing bar to the storage bin.

Product Description

The Automatic Hydraulic Pipe Bending Machine can be used together with NC-type steel shearing production line, which can automatically bend high-strength steel bars for construction. Compared with ordinary product on the market, it realizes the function to perform multi-directional bending at the same time in one work unit, and the two bending hosts can work at the same time, which greatly improves the efficiency, and greatly reduces labor intensity.

Operation Process

As the automatic pipe bender is an electronic device with a high degree of intelligence, its operation process is generally realized by professionals. The basic operation process can be simplified into the following steps. Let's have a look:

Normalization of tube shape -- standardization of bending radius -- determination of bending radius -- adjustment of bending forming speed -- determination of mandrel and its position

This is a title

1. bend-arm (C-axis) by hydraulic

2. clamp die, pressure die and side booster by hydraulic

3. motion up-down and motion left-right by hydraulic

4. carriage (Y-axis) by servo motor with programmable speed

5. collet (B-axis) grip by hydraulic, rotation by servo motor

6. mandrel by hydraulic with automatic lubrication & anticipated

retraction

7. IPC based controller :

Industrial PC assorted with touch-screen display, convertible

between manual / automatic mode, convertible between inch

metric setting, convertible between XYZ / YBC axes

capable of reading igs/stp file

8. PLC based controller :

PLC controller with touch screen display, convertible between

manual / automatic mode, convertible between XYZ / YBC axes

(optional)